100mm spacings what does it mean?

It is a very simple answer, every upright bar is spaced 100mm apart from the previous upright bar. That makes things quicker and cheaper to produce. Imagine having a railing where you drop the vertical bars in place. Dropping those vertical into locating “slots” where you know every one is 100mm apart from the next one. No need to measure, drop in in and weld it up. Assembly time for any railing is going to be much quicker, than individually measuring each bar.

Factor into that you can buy in mass produced parts that fit between a 100mm gap, cheaper than you can make them. You end up with a cheaper method of production that allows a lot of flexibility in design. Its that much faster to do that it can easy shave 30% off the time when compared to other methods of spacing. It almost sounds perfect doesn’t it.

The truth is that, it is far from perfect has a lot of cons to it. The question is do the pros outweigh the cons. To know that you need to understand the other method of spacing

Spacing V Centres

before i can explain the other method, there is something i need to explain that is common to both methods.

I talk about gaps between bars. But what i really mean is the centre position of the bar relevant to the previous bar. Minus the thickness of the bar. That sounds more complicated than it is. let me explain better.

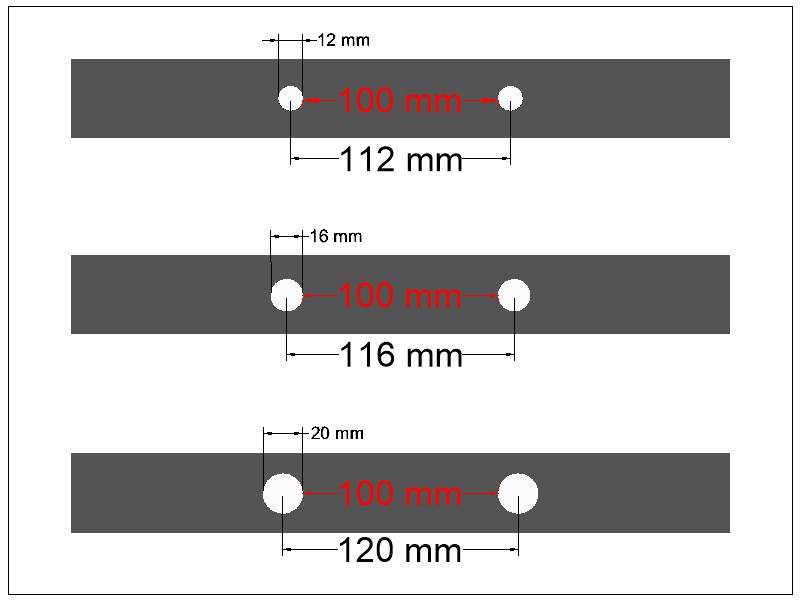

in order to get a 100mm gap between bars, i have to know the thickness of the upright bar i am using. If the bar is 12mm thick then i need to mark my bar centre positions 112mm from the next bar. If it is 16mm then it needs to be 116mm apart.

The drawing helps explain perhaps better than i can in words.

But a point to note with both methods, if you work it out based on using 12mm, then change your mind and decide 16mm is better. It will change the positions on your bar for marking. because of the increase centre positions on 16mm, it could mean you have a smaller number of uprights.

The other method.

As stated the other method is more complexed and requires some basic maths. Feel free to bypass the maths, but it does explain it. The short version is you aim for a maximum gap size but usually achieve a smaller size. The distance from the wall to the first upright bar is the same as the distance between all the other bars.

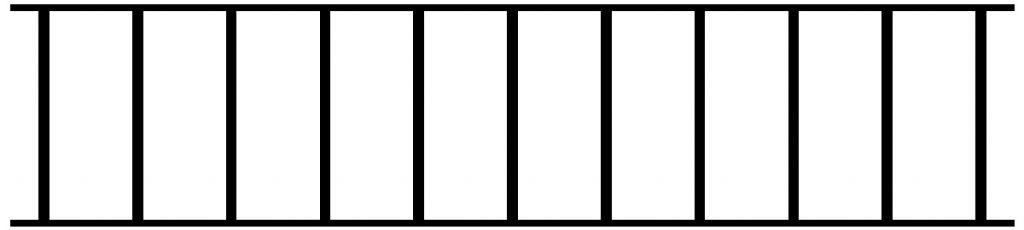

Take the length require of the railing. lets say 1200mm for the purpose of an example. Because you are working from centre positions of the bar. you need to add the thickness of the bar to your railing length. This might seem strange but look at the drawing below.

The red circles are where imaginary bars should be. so if we are using 12mm thick uprights, the centre of that upright would be half the thickness of the bar at each end. This might seem strange but this ensures that the gap from the end of the bar to the first upright bar is the same as the gap between all the rest of the bars.

So now we have a imaginary length of 1212mm. what we are looking for is a gap between bars of 100mm. so as we use centres we need to divide by 112mm.

1212 divided by 112 is 10.82…. What we were looking for here was a whole number with no decimal spaces. To get our 100mm gap between bars what we really wanted was a railing size of 1220mm it would have worked perfect.

If we round that 10.82 up to 11 and now divided 1212 by 11, we get 110.2 (near enough) or a gap between bars of 98.2mm. That’s close to 100mm but it might exclude us from using pre-made parts because they wont fit the gap,

now you have the bar centres you can mark out the positions where all the uprights need welding. But you have to hold them in place and tack weld into position before fully welding, just make to sure you made no mistakes. Its time consuming and often excludes you from using pre-made parts like scrolls. But what you get is perfect spacing. I love a perfectly spaced railing,

Now i know that dividing 11, means i didn’t get a centre bar. A centre bar might be all important to the design for this railing. I could correct that instead of dividing by 11, i could divide by 12. what i get is 101 centres, which means a gap between bars of 89mm. If every i had a chance of squeezing in pre-made parts before, that has now gone. But i do have that all important centre bar to work my design from.

You don’t exclude yourself from all the pre-made parts just the ones designed to fit in a 100mm gap. Twists and baskets are still on the menu.

The Cons.

now i never explained the cons of 100mm spacing. I left that for last until i had it explained the other method. because the answers are there.

We said a perfect size would have been 1220mm, but we have a size of 1200mm. What this means on the fixed space 100mm gaps, is the end bar is going to be 90mm gap between the wall and the first upright. And 90mm between the final upright and wall. But the rest of the uprights will be 100mm gap. We lost that nice even perfectly spaced look. Its only 10mm no one will notice. but if the railing length require was 1150mm instead of 1200mm. Well it just gets worse we are now 35mm off each end. That is noticeable, is it a bad look? i will leave that for you to decide.

I mentioned a centre bar before for the purpose of design. But we know the fixed gap railing has 10 uprights so no centre bar. Can one be forced?

It could be forced but it is going to make that end bar even closer to the wall. Squeezing an extra bar in will really close the gap on the end. instead of 10mm off based on the 1200mm railing. its going to be 34mm gap at the end. The standard simple adjustable wall brackets are going to foul on the end bar because there is not enough space. A drastically modified one will need to be made.

So now you can see the Cons with the fixed space. The size i choose was just a number plucked out of the air, but it was a good example to show how bad it could go wrong. it really does depend on the size of railing you need,