Metal wall railings.

Made to measure metal wall railings, literally hundreds of designs in our design library, we are bound to have something to suit.

Quick Navigation

Custom made.

Because there is almost no such thing as a standard size metal garden wall railing. All iron wall railings are made to measure. This means any specific decorative design in your wrought iron railings can be adjust to suit the length of the railing.

Not every garden wall is flat, if you have a shaped wall. It is not a problem I can make the wrought iron railing fit the profile of your wall. Its as simple as taking a profile of the wall, usually with a sheet of ply wood. This gives a representation of the wall to bring back to the workshop. Allowing the use of the template, to make a railing to match the profile of the garden wall.

Of course not every wall has a brick piers to bolt your metal railings to. The easy remedy is of course to use upright steel posts. Bolted to the wall with the steel railings then bolted to the posts.

The picture here, the wall is on a slope, the metal railings can be made to follow that slope. This was a long section of railings in Guildford on a wall with a small slope.

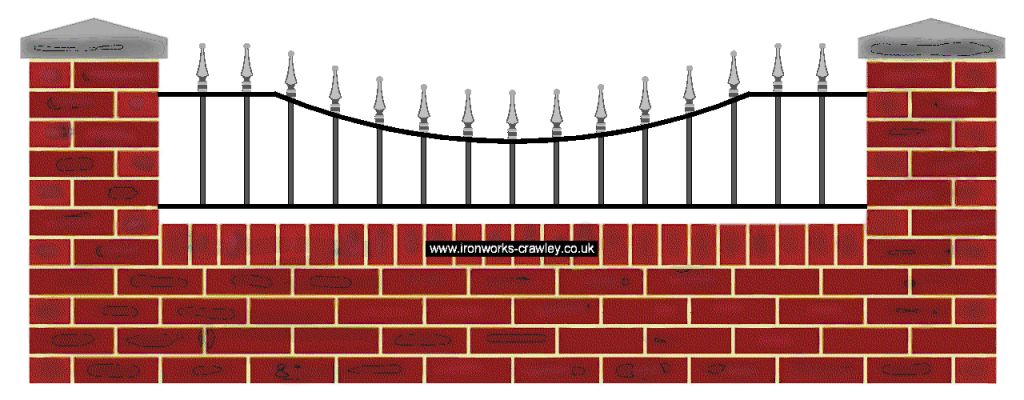

Metal garden wall railings can have a shaped top. Here a set of dip down iron railings on a flat wall with interconnecting steel posts. The curve of the dip can be adjusted to suit the length of the railing panels.

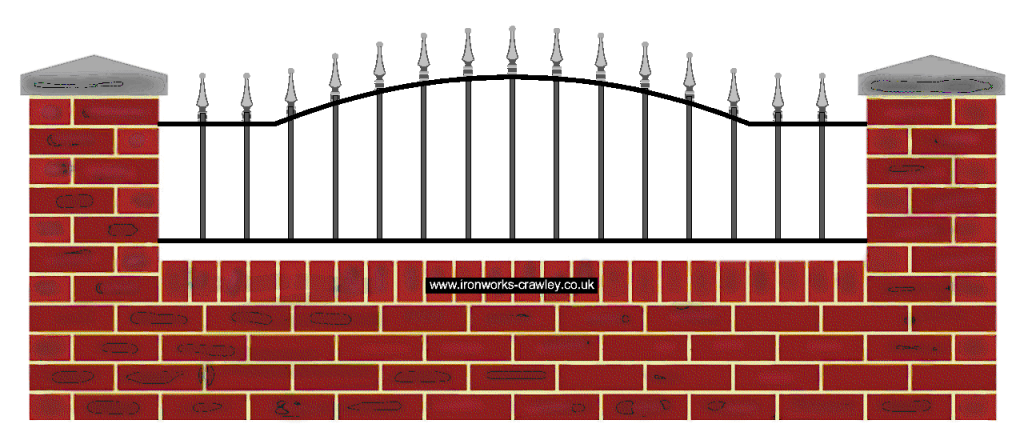

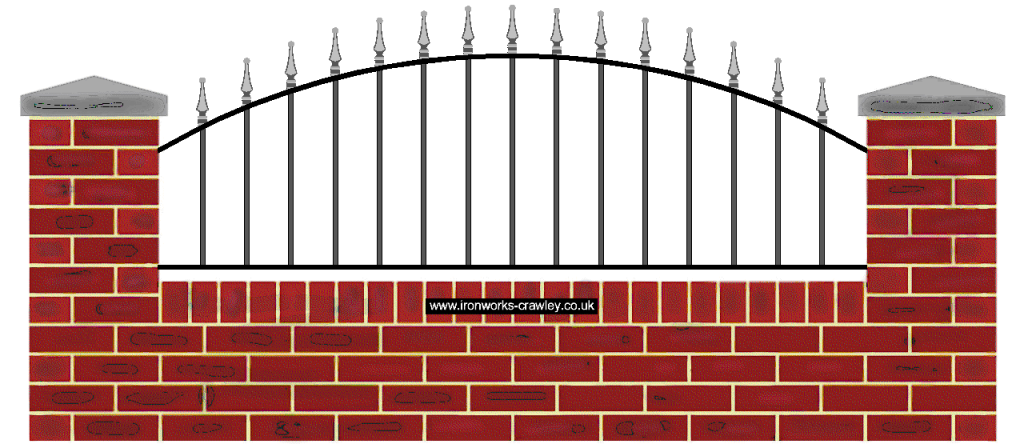

If a railing can dip down, it can also rise up in an arch shape. Decorative railing heads can be painted an alternative colour. Gold used here highlighting, the railing heads and the baskets in this wrought iron railing.

Railing height.

Railing height or should i say finishing height of the railings is all important. The 3 examples below all drawn on the same height brick pier but with the height of the metal railing being slightly different. This obviously depends on the configuration of your wall. But it is something to take into account.

Here the railing heads are set just below the capping stone

Set just above the top of the wall but below the top of the capping

Railing heads here are set to be level with the top of the capping.

If you don’t have a capping stone you are likely to have bricks on edge, a soldier course. The principle still applies but it usually level with the top or a bit below.

Railing shape.

Flat metal wall railings are always going to be the cheapest option, as they are the simplest to make. But steel railings can be arched or dipped. This is obviously additional work when compared to a flat railing as the arch has to be formed from a flat bar and bent into shape. But because I make to order this means the shape of the arch, can be made to your preferred shape.

Here is a shouldered arch. this starts flat and the centre section is then arched. There are two methods of doing this type of arch. One is to bend the curve get it the right height and length. Then to weld flat bar either side creating the shoulder effect.

The other method is to create a flowing type shoulder, where the bar is curved back to being flat. how much is curved and how much is flat is up to you as each curve is hand made.

When multiple shaped metal wall railings are required, its ideal if they are the same size. This keeps the arch the same shape and height. Although there is an element of flexibility on a shouldered arch. As the flat section can be longer or shorter. to keep the curve the same.

A full arch. this has no flat section which means when you have several panels. They really need to be the same length to preserve the shape of the arch. This can sometime cause issues if you have a stone capping or creasing tiles are used as in the photo above. This may mean the arch has to start a little low in order to clear an over hang. Alternative is tiny shoulder should to push it out beyond the over hang.

As with all arch wrought iron railing, how much the arch rises is up to you. it can be a gentle arch or a pronounced one. Because its made to measure, we can offer different shapes. Which is something you cant do with mass produce metal wall railings.

The dip style metal railing here is the same as the first shape metal railing image. But the top bar is literally welded on upside down, to form a dip. Care has to be taken here to make sure, the dip doesn’t reduce the height of the railing to much. Again like all shaped metal railings these are best suited when using multiple panels, with the panel length being the same size or at least very close in size.

Railing designs

We split metal wall railing designs into two separate pages. Those under 700mm and those over 700mm in height. The simple reason for this is that below 700mm tall there is a limitation into what can fit into the railing in terms of decorative bars. Above 700mm it becomes a little more easy due to the increased space to have more detail in the metal wall railing.

Mass produced v made to measure.

Mass produced

Mass produced metal wall railings usually come in limited size options, often only 6ft long. With a very limited number of designs. Very rarely do they come with a choice of colour options.. This is because its all about speed of production. With a limit on your size options, it become easy to make a jig tool for quick production. Drop the bars in the holder and weld them up. All spacings are set by the jig no measuring required, it doesn’t come any quicker than that.

With no disrespect to those that assemble them, it isn’t a high skilled job, just the ability to weld. These then usually tend to be plastic powder coated, again for speed. Many of the cheap metal wall railings tend to use thinner materials than would normally be used. Again this keeps costs down, certainly if you are using steel that’s half the weight. It reduces material costs in half. With so few options it become possible to have them in stock.

Cheap and in stock what is not to like. Except perhaps they all look the same, and tend to be of thinner construction, and possibly are not the correct size.

Made to measure.

With made to measure, you are not restricting yourself to a limited number of sizes, designs or colours. You are taking the sizes given to you by the customer. Working out the spacings of your upright bars on an individual basis. As each metal railing size is highly like to have a different gap between uprights. Marking you bar positions and welding each one in by hand. Any design decoration is also likely to be size specific.

So you will also have had to prepare a drawing for each size. Its highly likely to have spent 3 times as long making a size specific railing when compared to a set size one. Arguably it takes a bit more skill than just the ability to weld. Its highly likely you will be using far thicker material, than the cheap mass produce wrought iron railings. Simply because made to measure tends to be more about quality rather than quantity. But its also customer driven, so the majority tend to want the thicker look of heavier materials. But of course as its made to measure / custom made, changing material thickness is always an option.

Paint is often usually the preferred method of finishing, than plastic coating. Paint offers far more flexibility in terms of colour. Not only does it allow you to offer the metal wall railings in any colour, it also allows the options of “gloss” level. Matt, Satin, Semi gloss, full gloss. As well as the easy ability to add a secondary colour, like gold or silver railing heads. Unlike powder coat, paint has a longer setting or drying time. With often 24hrs needed between coats. Most good paint finishes are a 3 coat system. Etch, primer, top coat. making it slow for mass production.

A clear price structure for metal garden wall railings, can be an issue when doing made to measure. Because of the number of options having a simple price can be difficult.